Understanding Total Fatty Matter in Soaps

Soaps have been an integral part of human hygiene and cleansing rituals for centuries. From the ancient Egyptians and Babylonians to modern-day commercial soap production, these versatile products have evolved significantly over time. However, one crucial component remains at the heart of every soap formulation: fatty matter. Specifically, the total fatty matter content plays a pivotal role in determining the quality, efficacy, and overall performance of soaps.

In this article, we delve into the world of total fatty matter in soaps, exploring its composition, significance, and the factors that influence its properties. By understanding this essential aspect, consumers, manufacturers, and industry professionals can make informed decisions and appreciate the intricate science behind these everyday cleansing products.

What is Total Fatty Matter?

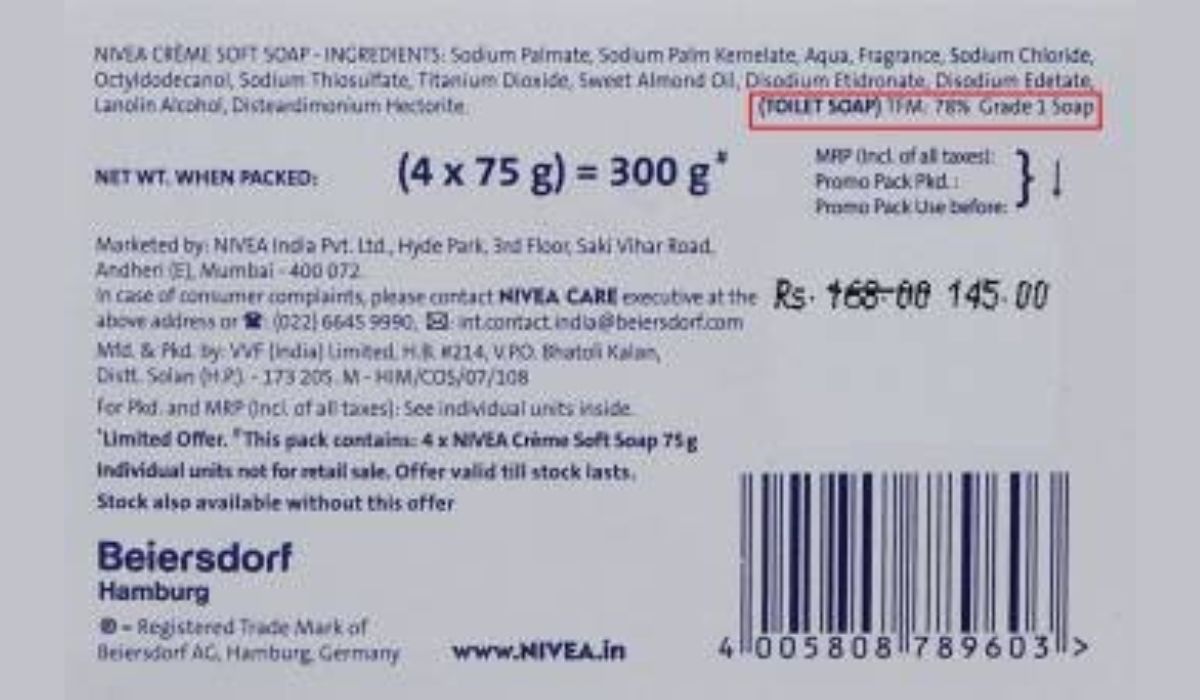

Total fatty matter, often referred to as TFM, is a collective term that encompasses the various fatty acid components present in soaps. These fatty acids are derived from different sources, including plant oils (such as coconut, palm, or olive oil), animal fats, or synthetic sources. The specific combination and ratios of these fatty acids contribute to the unique properties and characteristics of each soap formulation.

The Composition of Total Fatty Matter

Total fatty matter in soaps is primarily composed of three main types of fatty acids:

1. Saturated Fatty Acids: These fatty acids have a linear chain structure without double bonds, making them more stable and resistant to oxidation. Examples include lauric acid (found in coconut oil), palmitic acid (found in palm oil), and stearic acid (found in animal fats).

2. Monounsaturated Fatty Acids: These fatty acids contain one double bond in their carbon chain structure. Oleic acid, present in olive oil and other vegetable oils, is a common monounsaturated fatty acid found in soaps.

3. Polyunsaturated Fatty Acids: These fatty acids possess two or more double bonds in their carbon chain structure. Linoleic acid and linolenic acid, found in various plant oils, are examples of polyunsaturated fatty acids that can be present in soap formulations.

The specific ratios and concentrations of these fatty acids in the total fatty matter determine several key properties of the soap, including lather stability, cleansing ability, hardness, and skin compatibility.

The Significance of Total Fatty Matter

Total fatty matter plays a crucial role in the performance and quality of soaps, influencing several aspects:

1. Lather and Foam Formation: The fatty acid composition, particularly the ratio of saturated to unsaturated fatty acids, affects the lather and foam-forming abilities of soaps. Generally, soaps with a higher proportion of shorter-chain saturated fatty acids (such as lauric and myristic acids) produce richer, more stable lathers.

2. Cleansing and Emulsification: Fatty acids with different chain lengths and degrees of saturation exhibit varying cleansing and emulsification properties. Shorter-chain fatty acids tend to be more effective at removing dirt and oils, while longer-chain fatty acids contribute to the soap’s overall mildness and skin compatibility.

3. Hardness and Bar Longevity: The total fatty matter composition also impacts the hardness and longevity of soap bars. Soaps with a higher proportion of longer-chain saturated fatty acids (such as stearic and palmitic acids) tend to produce harder, longer-lasting bars.

4. Skin Compatibility and Moisturization: The fatty acid profile of soaps can influence their skin compatibility and moisturizing properties. Soaps with a balanced ratio of saturated and unsaturated fatty acids, particularly those containing monounsaturated fatty acids like oleic acid, are generally considered more gentle and moisturizing for the skin.

Factors Influencing Total Fatty Matter

The total fatty matter content and composition in soaps can be influenced by several factors, including:

1. Raw Material Selection: The choice of fats, oils, and other raw materials used in soap production plays a crucial role in determining the fatty acid profile of the final product. For example, coconut oil is rich in lauric acid, while olive oil is a good source of oleic acid.

2. Saponification Process: The saponification process, which involves the reaction between fats or oils and an alkali (such as sodium hydroxide or potassium hydroxide), can affect the final fatty acid composition. Parameters like temperature, reaction time, and the type of alkali used can influence the distribution of fatty acids in the soap.

3. Post-Production Modifications: Manufacturers may employ various post-production techniques, such as fractionation or hydrogenation, to modify the fatty acid composition and tailor the properties of the soap to specific requirements or preferences.

Quality Control and Regulatory Standards

Given the significance of total fatty matter in soap quality and performance, it is crucial for manufacturers to adhere to strict quality control measures and regulatory standards. Various organizations, such as the International Organization for Standardization (ISO), the American Oil Chemists’ Society (AOCS), and the European Committee for Standardization (CEN), have established guidelines and methods for the analysis and determination of total fatty matter in soaps.

These standards typically involve analytical techniques like gas chromatography (GC) or high-performance liquid chromatography (HPLC) to identify and quantify the individual fatty acid components present in the soap sample. By adhering to these guidelines, manufacturers can ensure consistent quality, comply with labeling requirements, and meet consumer expectations for their soap products.

Conclusion

Total fatty matter is the backbone of soap formulations, determining their cleansing abilities, lather quality, hardness, and skin compatibility. Understanding the composition and properties of fatty acids in soaps is essential for manufacturers, consumers, and industry professionals alike. By carefully selecting and combining the right fatty acid sources, manufacturers can create soaps tailored to specific needs and preferences, while consumers can make informed choices based on their individual requirements and desired soap characteristics.

As the science of soap-making continues to evolve, ongoing research and innovation in the field of fatty matter analysis and optimization will undoubtedly lead to the development of even more advanced and specialized soap formulations, catering to the ever-changing demands of the market and the pursuit of superior cleansing experiences.